Mamaton

The Superior Asphalt Modification System

What is Mamaton?

Mamaton denotes elastomeric polymer fibers applied as high-performance modifiers for bituminous binders and asphalt mixtures in highway and airfield pavement engineering. These fibers are instrumental in enhancing the rheological and mechanical properties of asphalt mixes, particularly with respect to fatigue resistance, rutting susceptibility, and low-temperature cracking performance. The incorporation process takes place during hot-mix asphalt production, placement, and compaction, using conventional construction equipment. A dedicated mobile blending unit is employed at the asphalt plant to generate polymer-modified bitumen (PMB) through a controlled in-line process. This rigorous production method ensures that the modified binder consistently complies with AASHTO and ASTM performance criteria for advanced pavement systems.

The production methodology delivers several engineering and economic advantages:

1-Reduced Transport and Storage Costs:

Modification is carried out directly at contractors’ storage facilities, minimizing the need for transporting pre-blended binders and reducing overall logistical expenses.

2-Operational Efficiency:

The elimination of supplementary storage tanks for multiple binder grades simplifies production logistics and accelerates construction workflows.

3-Retention of Binder Properties:

By avoiding prolonged storage and large thermal fluctuations, the system preserves the viscoelastic characteristics of the binder, preventing premature aging and performance degradation.

Collectively, these benefits provide a cost-effective and technically robust solution for producing premium-quality asphalt mixtures for demanding pavement applications.

Polymer-modified binders are produced under the supervision of experienced pavement technologists, who remain on-site to implement stringent quality assurance protocols and provide technical guidance during both production and field application. This ensures consistent binder performance and facilitates the optimal utilization of the polymer in asphalt mixtures.

Extensive laboratory evaluations and large-scale field trials have repeatedly confirmed the superior performance of this polymer system, demonstrating:

1-Reduced Permanent Deformation (Rutting):

Significant reduction of wheel-path rutting under heavy traffic loading, especially in hot climatic zones.

2-Mitigation of Thermal Cracking:

Utilization of softer base bitumen combined with the polymer network lowers susceptibility to low-temperature cracking.

3-Extended Fatigue Life:

Pavement service life is frequently doubled due to enhanced mixture stiffness, improved fatigue resistance, and superior aging characteristics.

4-Enhanced Aggregate-Binder Adhesion:

Strong bonding improves tensile strength before and after moisture conditioning, making the system suitable for demanding mixtures such as Stone Mastic Asphalt (SMA), Hot Rolled Asphalt (HRA), Open-Graded Friction Courses (OGFC), and stress-absorbing interlayers (SAM, SAMI).

Polymer-Modified Bitumen (PMB) is produced on-site, where binder characteristics are engineered to match project-specific requirements:

1-Climatic Adaptation:

Rheological parameters (e.g., penetration index, softening point, viscosity) are calibrated to withstand local temperature extremes.

2-Aggregate Compatibility:

Binder chemistry is optimized to interact effectively with locally sourced aggregates, improving mixture stability and cohesion.

3-Pavement Layer Optimization:

Key structural courses (base, binder, and wearing courses) are customized for improved load-distribution and service performance.

4-Construction Efficiency:

PMB production aligns with plant capacity and paving schedules, ensuring uninterrupted progress and on-time project delivery.

This project-specific customization process ensures that the modified binder meets all technical specifications, resulting in durable, reliable, and high-performing pavements.

Mamaton Polymer Binder Types

▪️The system encompasses a full spectrum of modified binders for various applications:

1-Mamaton 2020: Formulated for base and binder courses, with improved resistance to permanent deformation and fatigue.

2-Mamaton 2030: High-stability binder for heavy-duty traffic conditions.

3-Mamaton 2040: Optimized for dense wearing courses, ensuring superior durability and skid resistance.

4-Mamaton 2050: Designed for open-graded friction courses, enhancing surface drainage, safety, and noise reduction.

5-Mamaton 2060: Tailored for thin overlays, SAM, and SAMI membranes, with high adhesive and elastic properties.

6-Mamaton 2070: Developed for specialized applications such as SMA, HRA, and other performance-based mixes.

▪️The substantial extension of service life achieved with this system leads to a measurable reduction in maintenance frequency and reconstruction needs, thereby lowering the life-cycle cost (LCC) of highways and airfield pavements.

Method of Utilization

Developed by a team of experts and refined over several years, the elastomeric polymer has been deployed across diverse climatic zones, consistently demonstrating superior performance across various applications. Its proven efficacy lies in the project-specific design and production of the modified binder, carefully tailored to meet the unique environmental and traffic demands of each project. This polymeric binder enables the production of high-quality asphalt mixtures using locally available raw materials, supporting efficient and sustainable road construction.

The capacity of a pavement to adequately support traffic loads hinges on the mechanical and rheological properties of the asphalt mixture’s constituents, assuming an appropriate structural design and a subgrade capable of carrying the intended loads. By incorporating a proven modifier, the temperature operating window within which an asphalt concrete mixture can sustain the design load without undue distress is significantly widened.

The reduction in temperature susceptibility is achieved by simultaneously lowering the lower-bound temperature at which the binder film would crack and raising the upper-bound temperature at which the binder softens. This dual shift mitigates rutting and thermal cracking, thereby improving durability and service life.

Unmodified asphalt, limited by its inherent constraints, performs satisfactorily only within a narrow temperature range. The modified binder elevates mixture response as follows:

1-Base Binder Selection:

The first step is selecting a base bitumen with specific penetration and viscosity properties, chosen to prevent cracking at the lowest anticipated project temperature.

2-Extending the Temperature Range:

To further widen the service window, functional additives within the polymer system are selected according to climatic severity and traffic.

3-Higher Softening Point:

Modification raises the softening point (Ring-and-Ball per ASTM D36), reducing rutting under the highest site temperatures.

4-Elastic Response Range:

Polymerization broadens the temperature interval over which the mixture exhibits predominantly elastic/viscoelastic behavior, with low and high limits calibrated to project climate needs.

5-Process Modality:

The modification process involves adding selected hydrocarbon-based polymers to the asphalt— a plant-added/in-line process (sometimes referred to as the “planted polymer” process)— executed using mobile blenders at the hot-mix production site.

6-Polymer Architecture:

The polymerized hydrocarbons, primarily polyolefins, possess higher molecular weight than base-bitumen constituents. Their long-chain backbone and controlled side branching regulate crystallinity and enhance aggregate adhesion, which explains improved tensile properties before and after moisture conditioning.

7-Applicability:

The concepts above apply consistently to all types within the polymer system and to all asphalt mixtures produced with it.

The most important enhancements provided by the modifier to asphalt hot mix can be summarized as follows:

1-Significantly improved rutting resistance.

2-Reduced low-temperature crack initiation and propagation.

3-Enhanced load-distribution capacity at the structural level.

4-Lower fatigue damage under repeated traffic loading.

5-Increased adhesion and reduced moisture-induced stripping.

6-Diminished oxidative and UV-related aging.

7-Improved resistance to damage from lubricating oil and fuel.

Characteristics and Uses

▪️Mamaton 2020 is formulated for base and binder courses, the structural backbone of pavements. These layers must withstand permanent deformation, dissipate repetitive loads, and sustain heavy axle traffic. Over five years of service records confirm that the 2020 binder substantially improves structural stability and fatigue performance, thereby extending pavement life. It is recommended for highways with high traffic volumes as well as airfield runways and taxiways.

▪️Mamaton 2030 advances beyond 2020, targeting high-stability base and binder layers. Mixtures with this grade show low creep compliance, minimal rutting, and superior load-spreading capacity. Its reliability under severe traffic stresses makes it appropriate for freight corridors and high-speed roadways.

▪️Mamaton 2040 is customized for wearing courses, meeting the following performance demands:

1-Long-term skid resistance under varying traffic conditions.

2-Control of permanent deformation to ensure ride quality.

3-Retention of strength following moisture exposure.

4-Resistance to oxidative and UV-related aging.

5-Low abrasion loss and reduced stripping of fines.

6-Resistance to thermal cracking at sub-zero temperatures.

7-Resistance to fuel and lubricant damage.

To achieve these objectives, the 2040 formulation strengthens elastic recovery, stabilizes mixture response, and promotes aggregate-binder cohesion. Its wide operational temperature range is vital for surface courses exposed to thermal fluctuations.

▪️Mamaton 2050 is specified for Open-Graded Friction Courses (OGFC), with an air-void structure (~20%) that enables drainage and reduces hydroplaning. Benefits include:

1-Improved wet-weather safety and driver visibility.

2-Reduction of splash and spray, minimizing traffic hazards.

3-Substantial tire–pavement noise abatement, particularly in higher frequency ranges.

The 2050 binder demonstrates excellent elastic recovery, adhesive bonding, and mixture stability while controlling deformation. These attributes have driven broader international use of OGFC technologies.

▪️Mamaton 2060 is engineered for thin overlays and Stress Absorbing Membranes (SAM/SAMI). Thin courses restore worn pavements, while SAMI interlayers dissipate reflective stresses and improve waterproofing prior to overlays. The binder’s chemistry emphasizes tensile flexibility and adhesive strength, ensuring dependable performance in both asphalt and rigid pavement rehabilitation projects.

▪️Mamaton 2070 serves specialized mixtures, such as:

1-Hot Rolled Asphalt (HRA).

2-Stone Mastic Asphalt (SMA).

3-High-binder-content concretes for critical elements like bridge decks.

This grade delivers:

4-Increased oxidation resistance and long-term stability.

5-Enhanced moisture tolerance, reducing stripping.

6-Full prevention of aggregate loss from surface layers.

7-Superior rutting resistance under heavy traffic.

As with all system binders, the 2070 formulation can be adjusted with local aggregates and tuned to meet national standards, ensuring compliance with AASHTO M320/M332, ASTM D6373, and equivalent specifications.

Test Results

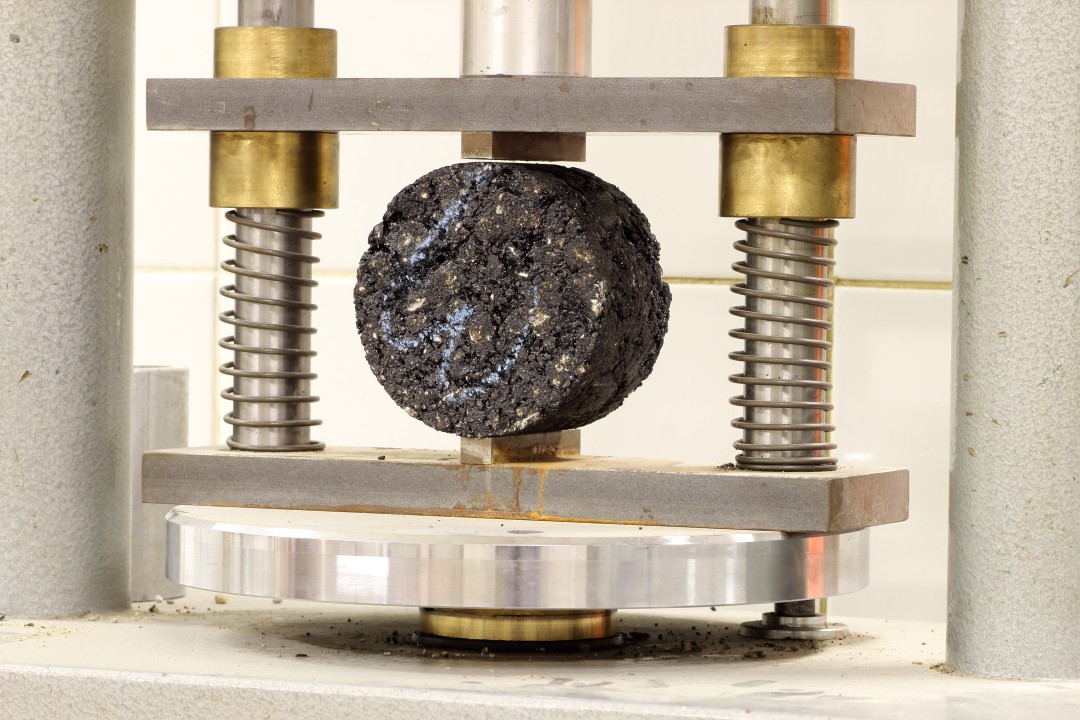

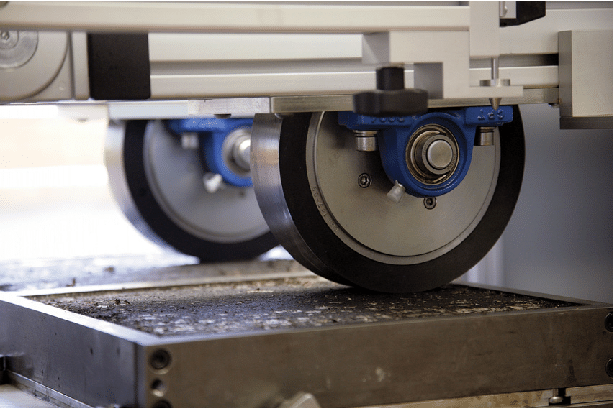

◾️Test 1: Wheel Tracking Test (Rutting Resistance)

Reference: Institute of Bitumen and Asphalt

Material: Asphalt Concrete

Method: Hamburg Wheel Tracking Device, based on AASHTC-132H / AASHTO T324.

This test involved both ordinary and polymer-modified asphalt mixtures. Slab specimens with dimensions 50 × 30 × 30 cm were compacted using a rolling compressor machine and frictional compaction method. The slabs were submerged in water at 50 °C. A loading wheel (20 cm diameter, 5 cm width) applied a constant load of 705 N while moving back and forth at a rate of 50 cycles per minute. A total of 20,000 passes were applied (10,000 forward + 10,000 backward).

Result:

1-Ordinary asphalt mixture: rut depth 6.62 mm with noticeable stripping along the wheel path under submerged conditions.

2-Polymer-modified mixture: rut depth 0.13 mm, demonstrating excellent rutting resistance and moisture stability.

◾️Test 2: Resilient Modulus Test

Reference: Institute of Bitumen and Asphalt

Material: Asphalt Concrete

Method: ASTM D4123 (Haversine load pulse, 0.1 s load, 0.9 s rest; 1 Hz).

Cylindrical specimens were tested at 25 °C. The resilient modulus was determined by applying repeated axial loads under controlled loading/rest cycles.

Results:

1-Polymer-modified mixtures showed a substantially higher resilient modulus (MR) at elevated temperatures, indicating improved elastic response and deformation recovery.

2-At low temperatures, MR values were similar for both modified and unmodified mixtures, confirming that thermal cracking susceptibility is not worsened by modification.

◾️Test 3: Dynamic Creep Test

Reference: Institute of Bitumen and Asphalt

Standard: BS DD226

Temperature: 45 °C

Slab specimens were subjected to a 100 kPa axial stress for 1 second over 1,800 load cycles (total test duration: 3,600 s). A 12 kPa pre-load stress was applied for 120 s before the cycles.

Results:

1-Unmodified asphalt exhibited progressive creep strain and early signs of deformation.

2-Polymer-modified mixtures displayed significantly lower creep strain, confirming higher resistance to permanent deformation under sustained stress.

◾️Test 4: Low-Temperature Behavior

Reference: Institute of Bitumen and Asphalt

Method: Thermal Stress Restrained Specimen Test (TSRST) and Direct Tensile Strength at multiple temperatures.

Specimens (prismatic beams) were cooled at a constant rate of 10 °C/hour while restrained, to measure thermal stress development. Additional tensile tests were conducted at +20 °C, +5 °C, –10 °C, and –25 °C.

Results:

1-Modified mixtures achieved higher maximum tensile strength and greater available tensile reserve across all tested temperatures.

2-The critical cracking temperature (intersection of tensile strength and thermal stress curves) was lower for modified mixtures, confirming superior resistance to low-temperature thermal cracking.

3-Polymer modification significantly improved fracture toughness and reduced temperature susceptibility compared with the control mixture.

The Use of Polymer-Modified Bitumen in Asphalt

Generally, the use of polymers in combination with bitumen aims to achieve the following two objectives:

1-Improving the existing performance properties and bringing them to the required quality.

2-Increasing the longevity and preserving the quality of bitumen in asphalt for consecutive years.

Although bitumen alone typically constitutes 4 to 5.5 percent of the total asphalt concrete, and it may seem that the role of bitumen in the behavior, durability, and performance of asphalt layers is not particularly significant, the truth is that bitumen and its physical and chemical properties have an important impact on the desirable performance, longevity, and stability of asphalt mixtures. Adding polymer to bitumen has positive effects on its properties and performance at high and low temperatures, altering all the characteristics of bitumen, which we will discuss further.

Today, a significant portion of government expenditures in various countries worldwide is allocated to asphalt pavement repairs, while these pavements deteriorate over time due to various factors such as loading and environmental variables, ultimately requiring substantial costs for repair, maintenance, or replacement of defective asphalt surfaces. Due to loading, asphalt pavements undergo deformation and experience stresses. Whenever the amount of horizontal tensile stresses in a pavement layer exceeds the tensile strength of its materials, it leads to cracking and breaking of that layer. Tensile strength is one of the most important parameters used to assess fatigue resulting from tensile stress in asphalt.

This parameter is calculated using appropriate laboratory methods and testing of suitable asphalt samples. As a result of studies conducted on the mixing of ordinary bitumen with Mamaton elastomeric polymer modifier which is produced in the form of filamentous polymer strands, all the performance parameters of bitumen have been enhanced, and in the asphalt mixture composition, it has successfully passed all laboratory tests formulated according to global standards.

Performance Grade (PG )(High-temperature range performance in summer and low-temperature range performance in winter): When asphalt is exposed to temperatures of 40 to 45 or -10 to -20 degrees Celsius, it undergoes significant degradation of its properties such as adhesion, softening point, ductility, and other characteristics, and it cracks due to shrinkage in freezing conditions (contraction cracks) and softens and flows at high temperatures in summer, raising the question of why, despite ideal grading, appropriate aggregate, optimal bitumen content according to the workshop formula and control, and monitoring of other specifications to an acceptable level, after one or two winters, asphalt deteriorates or, by retaining water for any reason, its surface becomes rough and uneven, and colloquially, the asphalt becomes naked.

Even a minor asphalt failure is like an open wound, and if not quickly repaired, with the penetration of water and air, especially water from the point of damage, asphalt degradation worsens and covers large areas, and under the influence of water, the fine particles of basic materials beneath the asphalt layer take on a fluid state and cause the asphalt to excessively flex, creating alligator cracks in it.

To achieve higher PG, polymers are used to produce highly resistant asphalts that can easily withstand a time span of 7 to 10 years and optimize expenditures in civil engineering.

Another important issue that justifies the use of polymer is the necessity of its use in asphalt with siliceous aggregates. As it is clear, if the aggregates used in asphalt are siliceous, the problem of bitumen separation from the aggregate arises over time. In other words, siliceous aggregates are bitumen repellent, meaning that good adhesion between them and bitumen does not occur, and with the presence of water in the asphalt body, which is inevitable due to rainfall, bitumen on the surface of the asphalt tends to separate from the aggregate and the phenomenon of aggregate stripping occurs, which is easily observable in asphalt pavements with a lifespan of several years, but with the emergence of polymer and its use in combination with bitumen, this problem is seriously addressed.

Next, we will discuss two other phenomena and problems in bitumens that affect the quality of asphalt.

As mentioned, with the passage of winter or excessive summer heat, many bitumen properties such as adhesion and ductility decrease, as well as its softening point. With the emergence of this problem, two other phenomena and crises arise, including aging of asphalt and early hardening of asphalt. Bitumen and asphalt hardening and aging are defined as follows:

Asphalt is always exposed to air, sunlight, environmental humidity, and ultimately oxidation. With the escalation of bitumen volatiles, asphalt experiences more oxidation and changes from dark to light colors, becoming harder and brittle over time. When the ductility and adhesion properties of bitumen decrease, the process of asphalt hardening and aging intensifies. Polymer materials maintain bitumen properties, delay hardening, and aging of bitumen, and increase the service life of asphalt.

The use of polymer materials in combination with bitumen improves all bitumen properties, prevents environmental factors from affecting it, and results in the following outcomes:

By using Filamentous Elastomeric Polymer, the following achievements are obtained:

-Prevention of aggregate stripping in asphalt mixtures. -Prevention of thermal contraction cracks.

-Reduction of deformation phenomena and bitumen bleeding on asphalt surfaces. -Prevention of asphalt cracks and the occurrence of reflective cracks.

-Reduction of hardening and aging of bitumen.

-Increase in fatigue resistance of asphalt mixtures.

-Increase in tensile strength of asphalt.

-Increase in bitumen softening point.

-Flexibility at low temperatures and no brittleness at the highest temperatures.

-Increase in compaction and reduction of air voids in asphalt.

For optimal utilization of polymer-modified bitumen in asphalt, a proper list of controls and inspections must be carried out. Failure to adhere to each of them will result in the asphalt not meeting the desired specifications, despite the use of polymer-modified bitumen.

The mentioned process is divided into 3 stages:

Stage One - Production of Materials and Storage at the Plant:

In the production of materials, adherence to the following parameters is essential:

1-Control of Los Angeles abrasion for coarse aggregate materials

2-Maximum weight loss with sodium sulfate (durability test) in coarse and fine aggregate materials

3-Maximum water absorption in coarse and fine aggregate materials

4-Maximum aggregate adhesion coefficient

5-Control of fracture percentage

6-Control of sand equivalent in the cold and hot intermediate stages

7-Quality control of filler (gradation - minimum binder content)

8-Gradation of coarse, intermediate, and fine aggregate materials

9-Control of proper stockpile formation at the asphalt plant site

10-Sampling of bitumen with supervision and conducting fivefold tests

11-Sampling of materials with supervision, conducting fivefold tests, and mixing design

12-Control of mixing design and its conversion into workshop formula

Stage Two - Calibration and Performance of the Plant and Control of Weighing and Production Systems:

1-Calibration assurance of weighing system

2-Control of bitumen storage location and tanker system, and heating method for bitumen reservoir

3-Weighing system control in bitumen and materials

4-Ensuring the integrity of screens and screeds

5-Control of dryer and heating method for materials, ensuring no settlement of fines on materials inside the dryer

6-Control of bitumen mixing time and conversion in the production tower

7-Control of bitumen temperature in the bitumen flux

8-Control of asphalt temperature during discharge to trucksStage

Stage Three – Asphalt Spreading, Compaction, and Operation:

This stage involves approximately 20 control points during asphalt spreading and execution.

First Use of Mamaton Modifier Polymer:

Regarding the use of polymer-modified asphalt, Mamaton polymer compound in a ratio of 1 to 10 was mixed with bitumen 60/70 and this project was implemented as a pilot for the first time in Iran and in the industrial town projects of the Markazi province. Asphalt sampling showed that the Marshall stability test had an upward trend and improved by 40% (between 1300 to 1350), and the flow of asphalt decreased to the range of 2.2 to 2.5. These results indicate a significant increase in shear resistance, load-bearing capacity, and fatigue resistance of asphalt. Alongside workshop tests, the laboratory located at the asphalt plant daily sampled bitumen ready for mixing in the bitumen flux and the results of penetration and softening point tests were recorded as follows over 6 sampling periods:

Softening 49-56 | Penetration 60-70 |

Celsius | 0.1 mm |

65 | 51 |

64 | 50 |

64 | 51 |

63 | 52 |

63 | 50 |

64 | 50 |

The above results indicate a decrease in penetration and an increase in softening point, showing a noticeable improvement. The increase in Marshall stability and softening point and the decrease in penetration and asphalt flow generally indicate an improvement in the performance of bitumen and asphalt, meaning greater durability and reliability of asphalt. Also, during PG tests previously conducted with this percentage of bitumen (10% blending with pure bitumen), the bitumen has upgraded from PG 64-22 to PG 76-28. Therefore, with this improvement, prevention of contraction and thermal cracks that usually occur in severe winters is achieved, and the polymer-bitumen combination with bitumen 60/70 increases the adhesion of aggregates to bitumen to an acceptable level, preventing aggregate stripping. Another achievement of using polymer-modified bitumen is obtaining desirable results in the Hamburg Wheel Tracking Test, which, under laboratory conditions, during the wheel tracking cycle of the Hamburg Wheel, in rutting conditions, has recorded approximately 50 times less change in asphalt layer compared to normal asphalt and no stripping problem that occurred for asphalt with pure bitumen without polymer has occurred for asphalt with polymer-modified bitumen. And as a result of the Sharpe test, the ductility and adhesion properties of bitumen have improved significantly.

All these advancements in polymer-modified asphalt indicate that despite a slightly higher financial burden of approximately 20% compared to regular asphalt during execution, polymer-modified asphalt is cost-effective overall due to its enhanced stability, durability, and longevity.

According to reports from various laboratories, up until the time of writing this text, no instances of deterioration have occurred in projects utilizing this type of polymer (Mamaton elastomeric polymer). Therefore, it has been well received by employers for use in other projects. It is worth mentioning that due to the high resistance and significantly improved properties of the asphalt, in many projects, reducing asphalt thickness by 20% has been feasible, offsetting the price increase resulting from the use of polymer. In other words, by reducing asphalt thickness by 20% and using 10% polymer-modified asphalt, project quality can be improved without incurring additional costs.

Mamaton polymer is employed in heavily trafficked routes in Iran, including Shiraz and Ahvaz, as well as in hot and humid regions of Sistan and Baluchestan province and in the route between Marivan and Sanandaj in Kurdistan province, which experiences cold weather conditions. After more than 10 years since the implementation of these projects, there have been no instances of technical problems such as reflective cracking, fatigue cracking, asphalt rutting and aggregate raveling reported from any project.

English translation of a number of statements issued by employers and their laboratories that confirm the validity of this claim are attached to this report.

It is worth mentioning that Laringum Knowledge Enterprise operates under the management of Fanico Holding, based in the United Arab Emirates. The filamentous elastomeric polymer modifier produced by this company has been registered under the trade name “Mamaton” in the UAE.

Fanico Group

Mamaton Expert Panel

I.R.Iran Number: 8590/171

|

Ahvaz Municipality Urban Development Organization

Ahvaz Municipality Urban Development Organization

|

Tehran Municipality

With reference to the services provided and the collaboration undertaken with the knowledge enterprise Laringum in the field of purchasing and utilizing elastomeric polymer for application in asphalt, and considering the time elapsed and the absence of any issues in the completed work sample, we hereby express our satisfaction with the provided product. We hope that, if necessary, continued collaboration with the company will be feasible.

|

Ahvaz Municipality

Ref: 1700/43189

Technical Deputy of the Organization for Planning and Budget and Secretary of the Technical Council of the Province

Following the reviews conducted by the technical and civil administration deputy of Ahvaz Municipality to address the undesirable conditions of urban streets in Ahvaz, and the numerous inspections and field visits, along with the solutions and actions taken in this regard, it is hereby notified. You are aware that Ahvaz city, located in the low-lying and depressed areas of Khuzestan plain with a high level of saline groundwater and waterlogged soils, is unsuitable for the implementation of sub-base and pavement layers. Given the periodic floods, the subgrade and pavement layers up to the asphalt sub-base are saturated, and it has been evident that traditional methods employed over the years are incapable of coping with this situation. Therefore, the need for the use of innovative methods in asphalt implementation is essential. Following the activities carried out over the past 12 years, the results obtained from the new asphalt mixing schemes in critical and waterlogged areas, as well as the use of polymer asphalt, have been remarkably significant. These schemes were piloted on Kianpars Street in 2013 and 2014, and the asphalt laid there, despite enduring repeated floods and stresses on the underlying layers, is operating without any issues. However, similar streets, resurfaced during the same period, have been frequently repaired and often remain in poor condition, indicating the coverage of underlying deficiencies and the durability and flexibility of the modified asphalt layer with this type of polymer. It is worth mentioning that the polymer in question belongs to Laringum knowledge-based company, the producer of the asphalt and bitumen modifier polymer, which is patented and certified by the Elite Foundation and endorsements issued by the Road and Urban Development Research Center and the Institute of Bitumen and Asphalt of the country.

1 of 2 Brief Benefits of Polymer Asphalt:

2- Possibility of reducing asphalt thickness by 20 to 40%, fully compensating for polymer usage costs during implementation. 3- Elimination of asphalt rutting, preventing surface roughness and light reflection. 4- 1000% resistance to rutting, a major problem in this region’s asphalt. 5- Increased lifespan of traffic markings and coloring, which have short lifespans in hot climates. 6- Improved Performance Grade (PG) of bitumen, preventing asphalt softening in hot summer weather. 7- Increased softening point, improving quality during implementation. 8- Reduction in permeability, leading to asphalt isolation and waterproofing.

Technical and Civil Deputy signed & Sealed

|

Ministry of Roads and Urban Development No. S/93/40109/

With reference to the request of Laringum Company in letter number 191/93 dated 27/02/2015, it is hereby informed that the implementation of filamentous polymer asphalt practically and experimentally on the Neiriz-Qatruyeh axis, between kilometers 770+60 to 205+65, by the contractor of this provincial administration, has been carried out. The outcome of the work performed, after three years and upon confirmation by the Institute of Bitumen and Asphalt of Iran and the opinions expressed by the Technical and Soil Mechanics Laboratory of Fars Province and the relevant consultant, is deemed acceptable and positive by this provincial administration. Therefore, the necessary measures are to be taken accordingly. This certificate is issued solely upon the request of Laringum Company and for submission to the Deputy of Planning and Strategic Supervision.

Director General Signed & Sealed

|

I.R.Iran Number: 13950

Subject: Performance Confirmation Certificate Following the contract concluded under number 13940 on 08/02/2017 regarding the purchase of Asphalt & Bitumen Filamentous modifier polymer, we hereby certify and confirm that the municipality is fully satisfied with the implementation of polymeric asphalt and the performance of your company. This is issued for informational purposes.

|

Functional Tests

Description and results of three functional performance tests conducted on the polymer-modified bitumen and polymer-modified asphalt mixtures by accredited laboratories:

TEST 1

Ministry of Roads and Transportation

Technical & Soil Mechanics Laboratory Headquarters

Technical & Soil Mechanics Laboratory

Fars Province Administration

Functional Tests on Bitumen and Asphalt Mixture Combined with Pure Bitumen and Polymer Modified Bitumen

(PMB produced by Laringum Enterprise)

Project Number:

070011344

Applicant:

Fars Province Roads and Transportation Administration |

April, 2011

Ministry of Roads and Transportation

Technical & Soil Mechanics Laboratory Headquarters

Test Results

Project Number:

910/2532

Applicant:

Fars Province Technical & Soil Mechanics Laboratory |

FR 122293/00

I.R.Iran Technical & Soil Mechanics Laboratory Headquarters

Respectfully, referring to letter number 7256/S 16 dated 29/10/2010 regarding the performance tests on bitumen and asphalt mixture with pure bitumen and polymer modified bitumen, the requested tests results are attached.

Mohammad Reza Nazarnijad Deputy of Educational and Research |

Asphalt Mixing Project

Table of Contents .................................................................................................................... Page

Introduction............................................................................................................. 1

1.Aggregate Material Specifications......................................................................................... 1

•Aggregate Material Grading................................................................................................. 1

•Quality Control Tests for Aggregate Materials........................................................................ 6..........................................................................................................................................

2.Bitumen Tests......................................................................................... 7

3.Aggregate Mixture Specifications....................................................................................... 12

•Determination of Mixing Ratios and Preparation of Aggregate Mixtures........................................... 12.......................................................................................................................

•Specific Gravity and Moisture Absorption of Aggregate Materials................................................. 14

4.Asphalt Mixture Specifications.......................................................................... 15

5.Determination of Optimum Bitumen Content........................................................................... 17...............................................................................................................

6.Modulus of Elasticity Tests..................................................................... 18

7.Dynamic Creep Test................................................................................... 19

8.Fatigue Test for Flexural Beams..................................................................... 20

9.Wheel Track Rut Test.......................................................................... 21

Introduction

This report is based on request number 7256/S 16 dated 29/10/2010 from the Technical & Soil Mechanics Laboratory of Fars Province regarding the preparation of a plan for hot asphalt mixture blending using aggregate materials and pure bitumen provided by the applicant, conducting performance tests on pure bitumen and polymer-modified bitumen provided by the applicant in a ratio of 20%, and conducting performance tests on asphalt mixtures containing pure bitumen and asphalt mixtures containing modified bitumen.

1. Aggregate Material Specifications

1-1. Aggregate Material Grading

Aggregate material grading tests were conducted according to AASHTO-T27 standard and washed method for fine aggregate materials. Additionally, grading and hydrometer tests were performed on the filler sample using AASHTO-T88 method. The results of the aggregate material grading tests are depicted in graphs 1 to 4.

Page 1

Right-click ➨ Open image in new tab for full view.

Page 2

Right-click ➨ Open image in new tab for full view.

Page 3

Right-click ➨ Open image in new tab for full view.

Page 4

Right-click ➨ Open image in new tab for full view.

Page 5

2-1- Quality Control Tests for Aggregate Materials

Tests for ascertaining the Atterberg limits (AASHTO-T89, T90), sand equivalent value (AASHTO-T176), assessing elongation and flakiness index (BS-812), calculating weight loss percentage against abrasion using the Los Angeles method (AASHTO-T96), evaluating percent weight loss in sodium sulfate solution (AASHTO-T104), determining percent crushed faces (ASTM-D5821), and measuring percent asphalt absorption by aggregate materials (AASHTO-T182) were conducted on the submitted aggregate materials, and their results are tabulated in Table Number 1.

Table 1 - Results of Aggregate Material Quality Control Tests

Test Results | Characteristics | |||

Aggregate Material Filler | Sand 0-6 millimeters | Coarse Aggregate Mixture | ||

- | 79 | - | Sand Equivalent Value (AASHTO-T176) | |

|

| B | Particle Size Distribution | Percent Weight Loss Against Abrasion by Los Angeles Method (AASHTO-T96) |

|

| 500 | Number of Revolutions | |

|

| 11 | Percent Abrasion | |

N.P | N.P | - | Plasticity Index (PI) | Atterberg Limits (AASHTO-T89, T90) |

- | - | - | Plastic Limit (PL) | |

Not determinable | Not determinable | - | Liquid Limit (LL) | |

|

| 100 | One-Face | Percent Crushed Faces on Aggregate Material Sieve No. 4 |

|

| 100 | Two-Face | |

|

| 17 | Elongation | Elongation and Flakiness Index (BS-812) |

|

| 15 | Flakiness | |

| 3.7 | 1.6 | Percent Weight Loss Against Sodium Sulfate (AASHTO-T104) | |

- | - | More than 95 | Percent Asphalt Absorption by Aggregate Materials (AASHTO-T182) | |

Page 6

2- Bitumen Tests

Common bitumen tests were conducted on samples of pure bitumen, and the results are presented in Table Number 2. According to ASTM-D1559 standard, the compaction and mixing temperatures of asphalt mixtures are determined based on the viscosity of the bitumen. For this purpose, the viscosity of pure bitumen was determined at three different temperatures: 120, 135, and 160 degrees Celsius. By plotting the viscosity changes of the bitumen against temperature on Graph Number 5, the range of compaction and mixing temperatures for asphalt mixtures was identified, and asphalt mixture samples were prepared and compacted for conducting mixing design tests at these temperatures.

Performance tests were conducted on the submitted pure and polymer-modified bitumens as follows, and the results for pure and polymer-modified bitumens are presented in Tables Number 3 and 4, respectively:

1- Rotational Viscometer (RV) Test according to AASHTO-T316 standard method on unaged bitumen (OB)

2- Dynamic Shear Rheometer (DSR) Test according to AASHTO-T315 standard method on unaged bitumen (OB)

3- Short-term Aging of Bitumen at 163 degrees Celsius for 85 minutes using Rolling Thin Film Oven Test (RTFOT) apparatus according to AASHTO-T240 standard method

4- Dynamic Shear Rheometer (DSR) Test according to AASHTO-T315 standard method on bitumen obtained from the Rolling Thin Film Oven Test (RTFOT) process

5- Long-term Aging of bitumen obtained from the Rolling Thin Film Oven Test (RTFOT) process in Pressure Aging Vessel (PAV) apparatus according to AASHTO-R28 standard method at a temperature of 100 degrees Celsius under a constant pressure of 2.1 megapascals for 20 hours

6- Bending Beam Rheometer (BBR) Test according to AASHTO-T313 standard method on bitumen obtained from Pressure Aging Vessel (PAV) procedure

Page 7

Right-click ➨ Open image in new tab for full view.

Page 8

Right-click ➨ Open image in new tab for full view.

Page 9

Right-click ➨ Open image in new tab for full view.

Page 10

Right-click ➨ Open image in new tab for full view.

Page 11

3- Aggregate Characteristics

1-3- Determination of Mixing Ratios and Preparation of Aggregate Mixtures

Based on the results obtained from the grading of aggregate materials and in order to achieve the median grading limit of No. 4 in the "table of Asphalt Mixtures Continuous Gradation", the mixing ratios of aggregate materials have been determined according to Table No. 5

Right-click ➨ Open image in new tab for full view.

Right-click ➨ Open image in new tab for full view.

Considering the ratios mentioned in Table 5, the percentage by weight of aggregate material passing through the desired sieves in grading No. 4 of the "asphalt mixtures continuous gradation table” is obtained as follows in Table 6:

Right-click ➨ Open image in new tab for full view.

Samples were prepared and constructed based on the median grading limit of No. 4 from the “Asphalt Mixtures continuous gradation table” using the aggregate material mixture. The aggregate material mixture curve used in the plan, according to the grading range of No. 4 in the mentioned table, is plotted in graph No. 6

Page 12

Right-click ➨ Open image in new tab for full view.

Page 13

2-3- Specific Gravity and Water Absorption Percentage of Aggregate Materials

Tests for determining the real specific gravity, apparent specific gravity, and water absorption percentage of the remaining aggregate materials on sieve No. 8 according to AASHTO-T85 standard, and the materials passing through sieve No. 8 and remaining on sieve No. 200 according to AASHT-T100 standard were conducted. The results of these tests, along with the real specific gravity value of the aggregate material mixture, are presented in Table 7.

Right-click ➨ Open image in new tab for full view.

Page 14

4- Asphalt Mixture Specifications

Samples of asphalt mixtures with different percentages of bitumen were prepared by applying 75 blows on each side of the sample using the Marshall method. The bulk specific gravity of the compacted asphalt mixture samples was determined according to AASHTO-T166 standard, and the strength and flow characteristics of the samples were determined based on ASTM-D1559 standard. The maximum theoretical specific gravity of the asphalt mixture for 6.0% bitumen content was determined to be 2.418 according to AASHTO-T209 standard, and the percentage of bitumen absorption by the aggregate material mixture (Pb2) was calculated to be 53%. Additionally, the maximum theoretical specific gravity of the asphalt mixture for different percentages of bitumen was calculated, and the results are presented in Table 8.

Right-click ➨ Open image in new tab for full view.

The percentage of compacted asphalt mixture air voids, percentage of voids in mineral aggregate (VMA), and percentage of voids filled with bitumen in mineral aggregate (VFA) were calculated based on the calculations outlined in MS-2 Asphalt Institute manual. The curves showing the variations of the above quantities with different percentages of bitumen are plotted in a series of graph(s) numbered 7.

Page 15

Right-click ➨ Open image in new tab for full view.

Page 16

5- Determination of Optimum Bitumen Content

The optimum percentage of bitumen in the asphalt mixture is obtained based on the graph(s)

7 and by considering the “Asphalt Mixtures Continuous Gradation Table.” This determination is made using either T245 or D5581 methods and considering the “Table of Aggregate Void Spaces” for determining the void in mineral aggregate, along with the recommendations of MS2 Asphalt Institute manual, resulting in 6.1% relative to the weight of the asphalt mixture. It is worth mentioning that other parameters of the asphalt mixture are controlled and within the specified allowable range for this percentage. It is evident that any changes in the particle size distribution of aggregate materials and mixing ratios necessitate reevaluation and control of asphalt mixture parameters, including the optimum bitumen content.

Right-click ➨ Open image in new tab for full view.

Right-click ➨ Open image in new tab for full view.

Page 17

6- Indirect Tensile Strength Test

The indirect tensile strength test of ordinary and polymer-modified asphalt mixture samples was conducted at a temperature of 25 degrees Celsius according to ASTM-D4123 standard method. In these tests, a half-sine waveform loading with a loading frequency of one hertz, a loading cycle duration of one second, a loading time of 1.10 second, and a rest time of 9.10 second in each loading cycle were used. The results of the indirect tensile strength test for ordinary asphalt mixture samples and polymer-modified samples are presented in Table 9.

Right-click ➨ Open image in new tab for full view.

Page 18

7- Dynamic Creep Test

The dynamic creep test of ordinary and polymer-modified asphalt mixture samples was conducted at a temperature of 45 degrees Celsius according to the BS-DD226 standard method. According to the standard, the test duration was 3600 seconds, during which 1800 loading cycles were applied, with a loading duration of one second at 100 kPa pressure in each cycle. Additionally, in this test, a pre-loading stress of 12 kPa is applied for 120 seconds before the test cycles. The results of the tests are presented in Table 10.

Right-click ➨ Open image in new tab for full view.

Page 19

8. Asphalt Mixture Beam Flexural Fatigue Test

To conduct the asphalt mixture beam flexural fatigue test, specimens of regular asphalt mixture and polymer-modified asphalt mixture were prepared using a roller compactor device. These specimens were then cut into beam-shaped samples according to AASHT-T321 standard dimensions. The results of the beam flexural fatigue test for regular asphalt mixture and modified specimens, in accordance with the mentioned standard, at a temperature of 20 degrees Celsius and strain levels of Strains [10^-6 * 250] and [10^-6 * 400], are presented in Table 11.

Right-click ➨ Open image in new tab for full view.

Page 20

9- Wheel Track Rut Test

The wheel track rut test of ordinary and polymer-modified asphalt mixes was conducted using the Hamburg Wheel Tracking Device according to AASHTO-T324 standard.

In this device, the loading wheel moves back and forth on the sample surface under dry or submerged conditions. The samples used in this device have dimensions of 30x30x5 centimeters. The loading wheel of the device has a diameter of 20 centimeters and a width of 5 centimeters. The samples were compacted using a roller compactor, employing a rubbing method for compaction. The asphalt mix slab samples were submerged in water at 50 degrees Celsius, with a wheel load of 705 Newtons and a reciprocating speed of 50 cycles per minute, undergoing 20,000 wheel passes (10,000 reciprocations). The depth of rutting in different cycles for ordinary and polymer-modified asphalt mixes is presented in graphs 8 and 9. The rut depth of the ordinary and polymer-modified asphalt mix samples after 20,000 wheel passes was 6.62 and 13 millimeters, respectively. It is worth mentioning that the ordinary asphalt mix, under the influence of water along the path of the wheel load movement, experienced surface stripping damage, leading to further rutting.

Page 21

Right-click ➨ Open image in new tab for full view.

Page 22

I.R.Iran

1.Comparative analysis between the results of pure bitumen and polymer modified bitumen tests has unequivocally demonstrated a 2-degree enhancement in bitumen performance with the utilization of polymer modified bitumen. 2.The modulus of resilience tests conducted on conventional and polymer modified asphalt mixes at 25 degrees Celsius has revealed that the incorporation of polymer modified bitumen has not led to excessive hardening of the asphalt. This observation underscores the superiority of polymer modified bitumen in enhancing asphalt properties without compromising its flexibility. 4.Fatigue tests conducted on beam-shaped asphalt mixes, both conventional and polymer modified, have revealed that the fatigue life of polymer modified asphalt mixes is approximately three times longer than that of conventional asphalt mixes, demonstrating the enhanced durability and longevity of polymer modified asphalt mixes. 5.Rutting tests (Wheel Tracking) carried out on conventional and polymer modified asphalt mixes have demonstrated that polymer modified asphalt mixes exhibit significantly reduced rut depths compared to conventional asphalt mixes. Furthermore, the stability of polymer modified asphalt mixes has been maintained under the influence of water, showcasing their exceptional durability and resistance to environmental factors. Yours sincerely, Freydoun Shahrivar Director-General

|

Page 23

TEST 2

Ministry of Roads and Urban Development

Technical and Soil Mechanics Laboratory

Tehran Province General Department

Test Results

Job Number

070021382

Applicant:

Laringum Enterprise

I.R.Iran Technical and Soil Mechanics Laboratory

Respectfully, with reference to the letter dated October 12, 2013, enclosed herewith are the test results of the requested tests conducted on pure bitumen (bitumen 60/70 available in the laboratory) and the polymer-modified bitumen sent by the applicant.

|

Right-click ➨ Open image in new tab for full view.

Test 3

Date of issue: 2017/june/31 | Test Report Of TEHRAN REFINERY |

PASARGAD OIL CO.. | ||||

Adress: Tehran Refinery - pasargad oil company | Phone & Fax: +982155214858 | |||||

Bitumen Grade: PG 64-22 | Tank No: ---------- | |||||

Tank NO: ………… | Date of Sampling: 96/02/11 | |||||

Code of the Sample in the laboratory: TE-96-O-21 | ||||||

Laboratory environmental conditions: Temperature (°C): 25±3 °C, Humidity (%): ≤ 60% | ||||||

Row | Test | Test Method | Result | Unit | Acceptable range | |

1 | Viscosity at 135°C | ASTM D4402 | 0.63 | Pa.s | Max 3 Pa.s | |

2 | Flash Point | ASTM D92 | 304 | °C | Min 230 °C | |

3 | Orig. Dynamic Shear G*/siδ | ASTM D7175 | at 64 °C (1.24) | Кра | Min 1.00 Kpa | |

4 | RTFOT, Mass Loss | ASTM D2872 | <1 | % | Max 1 % | |

5 | RTFOT, Dynamic Shear G*/sinδ | ASTM D7175 & D2872 | at 64 °C (2.68) | Кра | Min 2.20 Kpa | |

6 | PAV, Dynamic Shear G*.sinδ | ASTM D6521 & D7175 | at 19 °C (3490) | Кра | Max 5000 Kpa | |

7 | Creep Stiffness, S Test Temp @ 60 s, °C | ASTM D6648 | at -12 °C 114.38 | Mpa | Max 300 Mpa | |

8 | M-Value Test Temp @ 60 s, °C | ASTM D 6648 | at -12 °C 0.303 | …… | Min 0.3 | |

9 | Polymer Percent | 10% | Wt | …………….. | ||

1)This certificate shall not be reproduced except in full and without the written approval of the laboratory.

2) The technical competence of the pasargad oil company's laboratories has been approved by the " National Accreditation center of Iran (NACI)" and the "Institute of Standard and industrial Research of Iran (ISIRI)" as the accredited laboratories.

Laringum Knowledge-Based Company is a scientific and research subsidiary of Fanico Group |